In the early days of automobiles engine vacuum was a cheap and efficient source of powering devices. This was especially so with early cars having generators rather than alternators which limited the amount of current available to power electrical devices. Engine (manifold) vacuum was suited to powering many devices in a car, however, it does vary significantly with engine conditions. It is highest under deceleration and lowest under full throttle.

A very common use for engine vacuum was to power the windscreen wipers, however, varying manifold vacuum levels meant that the windscreen wiper speed would vary dramatically as the car accelerated and decelerated. Under full open throttle the wipers would even stall, not a good situation to be in when driving in heavy rain. To (partially) rememdy this, manufacturers installed a supplementary vacuum pump to provide additional vacuum when the manifold vacuum was low.

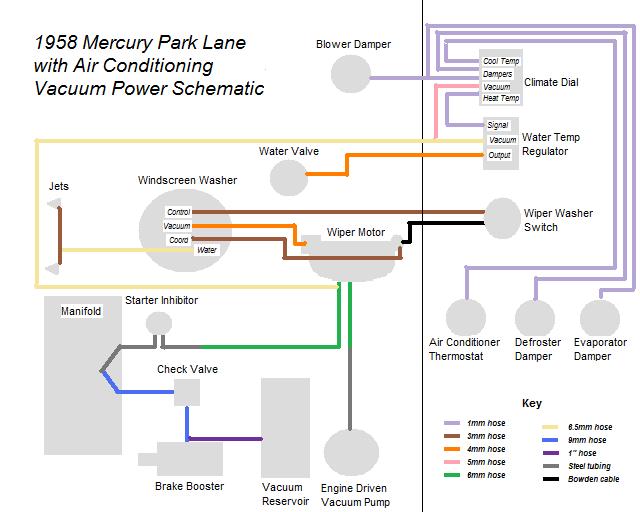

The 1958 Mercury made very extensive use of engine vacuum. It was used for all of the following:

- Windscreen wipers

- Windscreen washer

- Power brakes

- Starter motor inhibitor switch

- Heater water valve

- Heater and air conditioner duct flaps

- Air conditioner compressor switch and thermostat

Interestingly, Mercury installed a vane-type vacuum pump on the back of the oil pump, inside the engine, to provide the supplementary vacuum. Most manufacturers used a diaphragm pump mounted externally on the back of the fuel pump.

Following is a vacuum schematic for my car that I created when I had some time one rainy afternoon.

The vacuum hose in my 1958 Mercury looked fairly sick when it arrived. Much of the hose was cracked where it was pushed over a nipple. The windscreen washer and wipers didn't work either. Vacuum is very powerful when the circuit is airtight but the smallest air leak virtually renders it useless. Additionally, vacuum leaks affect the functioning of the carburettor and thus cause poor engine performance. Indeed, my car seemed to be running very roughly when it arrived but once I disconnected all the unnecessary vacuum hose it ran much better. It's always wise to replace all vacuum hose if it is old, even if it looks fine.

I took stock of what hose sizes I needed by measuring the nipples with the vernier calipers and then choosing the next size hose

down. Unfortunately when I went shopping for hose it became evident that I could only buy metric sizes in Australia whereas my car really needed Imperial sizes so I did a metric conversion. In all, my car uses 7 different sizes of vacuum hose. In typically Australian style I had to visit three parts stores to get all the hose I needed. Nowhere here ever stocks everything you want. It took two sessions to replace all the hoses. It's a surprisingly onerous task to reroute new hose where the old hose was, through the firewall and up into the dashboard. Of course I wanted to make it look as much like the original hose as possible. When it was finished the new hose looked so much nicer than the old cracked and dirty hose. What's more the engine no longer runs roughly and the windscreen washer works. The windscreen wiper still doesn't work but that will have to be for another day.